All stairs serve a common purpose – transporting masses of people vertically through a portion of a building, seamlessly (and typically quite unenthusiastically) linking each floor together. A staircase can be as simple as a series of sloping stringers with an intermediate landing where the code requires. When entering any emergency egress stairs, most will likely not consider the structure allowing them to exit the building safely. When the opportunity arises to make a staircase one of the central architectural features of the building, however, the design decisions begin to pile up quickly. How deep can the stringers be before they start to fill up the space? Should the stairs be supported by posts down to each sequential level below, or should they hang from the structure above? Will the structure be straight, curved, or both? These questions needed answers for the central staircase at EXP, Northeastern University’s new science, engineering, and laboratory building.

Photo Credit: Northeastern University Global News

EXP’s sister building, the Interdisciplinary Science and Engineering Center (ISEC), was also designed by Payette and LeMessurier. ISEC and EXP complement each other in several ways, each bounding one side of the recent expansion of the campus over the railway tracks that run through the larger campus. Like EXP, the ISEC central staircase is also a major architectural feature. The staircase spectacularly hangs off the edge of each floor with no hangers or posts to be found, spiraling up through the central atrium. As stunning as it is, the ISEC staircase required several-foot deep steel plate stringers to allow it to cantilever off each floor without any additional support. The stringer depth was one of the initial topics of conversation amongst the design team for the EXP stair. While it would be stunning to design another truly cantilevered staircase where the only support points are at the floor landings, the depth of the stringers required to limit the vertical deflections and vibrations would restrict the view beyond the stairs and quickly fill up the surrounding space in the EXP central lobby. Moreover, deep stringers would not create the staircase’s desired slender, “floating” appearance.

Steel hanger rods were strategically placed to provide extra support points to shorten the stringer depth. One rod was added at each connection between the stringers and the intermediate landing, and another was centered on the back of the intermediate landing. The goal was to limit the number of hangers while placing them strategically so the staircase may appear floating in mid-air at first glance. Adding hangers reduced the effective span of the stringer elements and thus greatly reduced the demand on the stringers compared to a purely cantilevered structure, allowing for a shallower 12-inch stringer depth to be used.

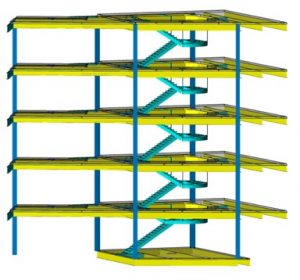

Extents of the analysis model.

While preliminary hand calculations were used to validate the approximate size of the elements, experience had shown that a 3D model incorporating the relative stiffness of the stair elements and the supporting base structure would be required to predict the deflection and vibrational behavior more accurately. The guidance outlined in AISC Design Guide 11, “Vibrations of Steel-Framed Structural Systems,” Second Edition was used for vibration design. Chapter 4 of the Design Guide recommends limits to the natural vibrational frequency to keep vibrations outside of the range humans can generally perceive. Since the EXP staircase is quite atypical as it is curved in plan, supported by hangers, and therefore reliant on the stiffness of the supporting floor structure, a finite element model of the stairs and the supporting structure was built according to the recommendations in Chapter 7, “Finite Element Analysis Methods.” A dynamic analysis was run to evaluate the natural frequencies and acceleration magnitudes, which were compared against the Design Guide 11 recommendations.

Because the hanger rods are supported close to the mid-span of roughly 45-foot structural steel floor beams, the stiffness of the beams contributed significantly to the overall vertical stiffness of the staircase. When analyzed in isolation, the stair structure appeared very stiff in the vertical direction. Only when the full stiffness of the supporting base building structure was incorporated was it apparent that some stiffening of the base structure would be required for the staircase to meet the Design Guide 11 vibration recommendations.

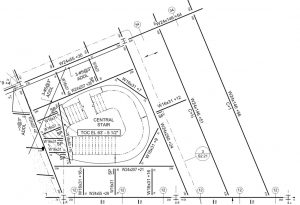

Central stair location within supporting framing.

For the horizontal vibrations, the analysis exhibited natural modes of vibration where the staircase wanted to swing side to side, as lateral support is only provided at the stringer connections to the base structure, and the steel hanger rods do not contribute to the lateral stiffness. The only way to stiffen the stair structure laterally was to turn it into an in-plane rigid frame. The rigidity comes from the steel stair treads and risers welded to the stringers for the full height of the staircase. Hollow structural section (HSS) tube members were added to tie the curved portion of the intermediate landings together to add even more stiffness.

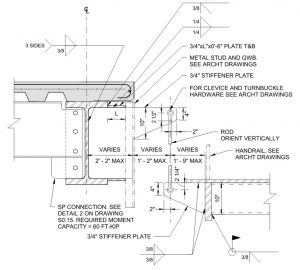

As for the steel hanger rods, there are no partitions around the staircase where they could be located to hide them from view. Therefore, the exact placement, size, and connections of the rods to the stair structure were important design considerations. The final decision was to extend steel stiffener plates from the supporting wide flange floor beams above and from the side of the exterior stair stringers to allow the hanger rods to be offset from the staircase while also centered between the stairs and the edge of the floor opening above. Although the hanger rods are visible, offsetting them from the main stair structure adds to the intended “floating” effect.

Stair hanger connection detail.

Once the strength and stiffness of the staircase were buttoned up, more work was still needed to ensure the staircase met the architectural intent. Architecturally exposed structural steel (AESS), as defined by the AISC Code of Standard Practice, was specified for all elements of the central staircase. As the staircase is fabricated from many individual steel elements joined together, the primary goal was to limit any visible gaps, welds, and rough surfaces when viewed close-up. Specifying AESS requirements, such as sanding surfaces, filling gaps, and smoothing welds, ensured the final product met the architectural finish requirements.

The design of a central staircase is one of the prime examples where architecture and structure must work seamlessly together to achieve the intended result. In this case, the structure is the architecture, and the architecture is the structure. The EXP central staircase exemplifies this perfectly. Initially conceived by Payette as a fully exposed, slender, “light” steel staircase, the team worked to realize this vision while meeting stringent structural performance standards. The result is a glowing white central staircase linking the central artery of the building together, illuminated by natural light shining down from a skylight above, sizeable enough to make an impression on those who use the space while also slender enough to blend right into its surroundings.

Northeastern EXP Floating Staircase from below while under construction.