To answer what is typically the first question, no, ‘EXP’ doesn’t stand for anything. The most apt description offered so far is ‘Exciting Place,’ coined by National Science Foundation Director Sethuraman Panchanathan during the building’s recent ribbon-cutting ceremony. While there are any number of parts of Northeastern University’s new science, engineering, and laboratory building that could earn it the moniker of ‘Exciting,’ the brand-new two-story robotics lab is easily the most prominent. Situated behind floor-to-ceiling glass walls, the robotics lab will be the first thing you interact with when approaching EXP’s front door along Columbus Avenue.

To answer what is typically the first question, no, ‘EXP’ doesn’t stand for anything. The most apt description offered so far is ‘Exciting Place,’ coined by National Science Foundation Director Sethuraman Panchanathan during the building’s recent ribbon-cutting ceremony. While there are any number of parts of Northeastern University’s new science, engineering, and laboratory building that could earn it the moniker of ‘Exciting,’ the brand-new two-story robotics lab is easily the most prominent. Situated behind floor-to-ceiling glass walls, the robotics lab will be the first thing you interact with when approaching EXP’s front door along Columbus Avenue.

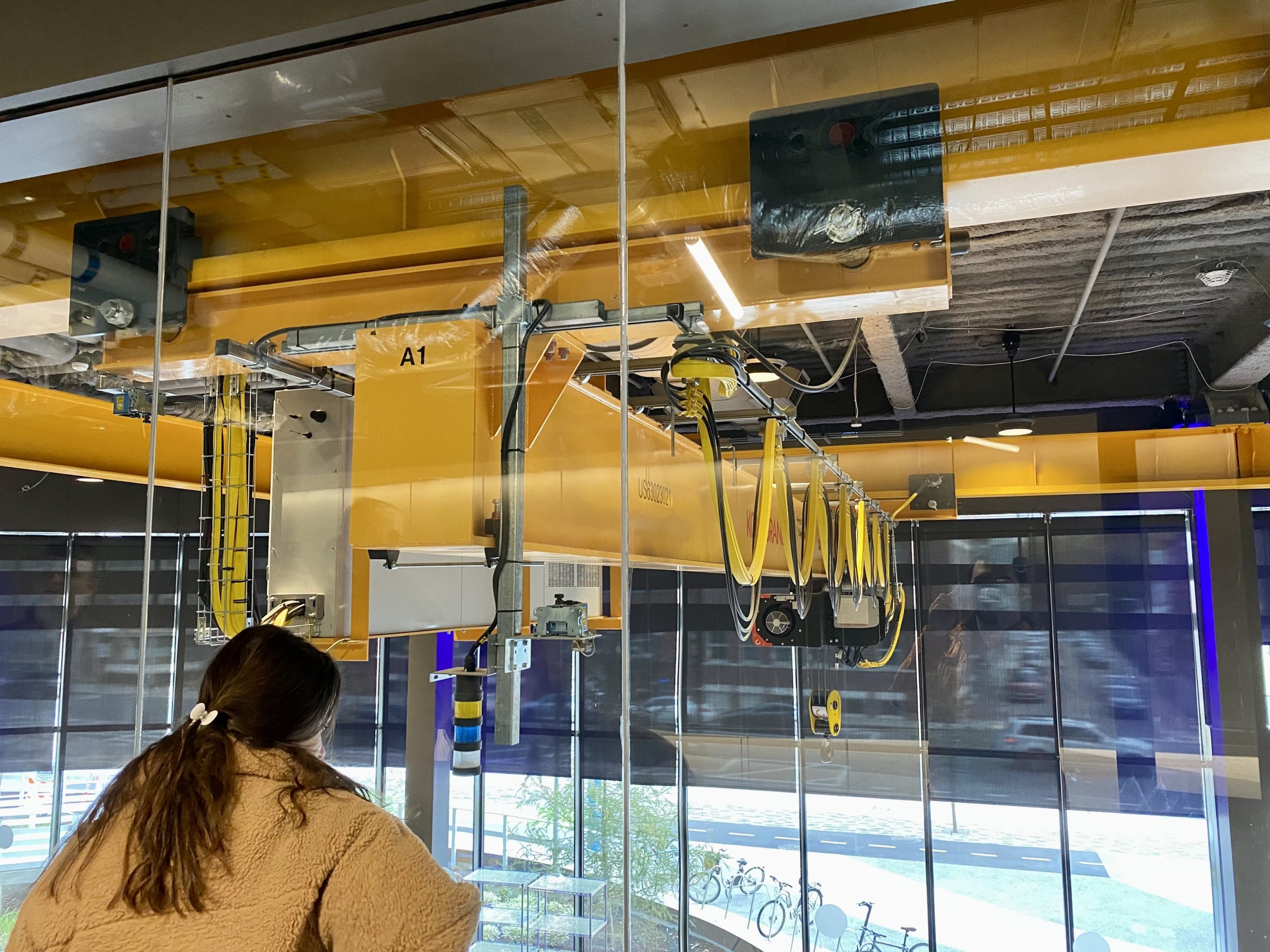

The interior of the robotics lab is functional first to allow heavy-duty testing of robots in a column-free space over various terrains in all testing configurations. Offset from the industrial feel of the space, the building columns are awash in blue light and contrasted above by a vibrant yellow gantry crane. While it’s not exactly a sun in the sky, the crane certainly stands out and does so as a major showpiece of the space. Seeing the crane from outside the building is one thing, but watching it up close once you’re inside is an entirely different experience.

The two-story high robotics lab is a tall, dramatic space, abutted further to the inside of the building by individual stories of corridors, study lounges, and a future retail market. As on the exterior, the interior sides of the robotics lab are floor-to-ceiling glass to embrace and showcase the state-of-the-art research being advanced. Keeping the crane from obstructing the view from the second floor is critical to having the robotics on display. That way, anyone in the adjacent lounge can walk up to the glass, peer out over the large laboratory and marvel at the micro-level finesse of the electronics in the robot while being confronted with the macro-level muscle of a moving crane that can lift 25,000 pounds.

The two-story high robotics lab is a tall, dramatic space, abutted further to the inside of the building by individual stories of corridors, study lounges, and a future retail market. As on the exterior, the interior sides of the robotics lab are floor-to-ceiling glass to embrace and showcase the state-of-the-art research being advanced. Keeping the crane from obstructing the view from the second floor is critical to having the robotics on display. That way, anyone in the adjacent lounge can walk up to the glass, peer out over the large laboratory and marvel at the micro-level finesse of the electronics in the robot while being confronted with the macro-level muscle of a moving crane that can lift 25,000 pounds.

Positioning the crane in the vertical space became a driving decision in giving life to the interplay between the micro and the macro. Positioning the hook height of the gantry crane above the robotics floor, which is useful for experimentation, put the structural systems supporting the crane very near eye-level in the viewing gallery on the second floor, so it was time to get creative.

Given the opportunity, structural engineers typically default to providing a structure that is the most cost-conscious version available – for gantries, cost-conscious is synonymous with a top-running crane. In a top-running scenario, the runway beams are continuous and the trolley travels along the top of the beams, where the crane hoist zips from side to side. The top of the runway beam must be unencumbered to allow the gantry to travel, and the runway can be seated directly atop the supporting structure. At EXP, the runway beam had to be about 24” to 30” deep and four to six feet above the loading gallery floor – right where it shouldn’t be. Understanding the geometry of the building and the desire to see the gantry in action, the team moved to a less conventional, underrunning crane system. The hook height would remain the same, but the runway beam would be positioned above the crane, so it would now be from six feet to eight feet above the viewing gallery, above eye level.

The runway beam for an underrunning crane presents technical challenges:

The runway beam for an underrunning crane presents technical challenges:

- The crane is suspended from the bottom flange of the runway.

- The runway bottom flange must be unencumbered from any physical interference.

- The gantry is positioned beneath the runway, so support from the runway is from above.

- The support for the runway cannot be on a column line (encumbrance).

Once a solution for moving the runway beam out of the primary field of vision was in place, technical engineering followed. This included solutions for resolving the forces acting on the bottom of the runway, including self-weight and the lifted load (collected as ‘Cv’), vertical impact and seismic forces (as ‘Ci’), inertial forces from mobilizing and braking the trolley along the runway, and longitudinal seismic forces (as ‘Cl’), inertial forces from the hoist and transverse seismic forces (as ‘Cs’), many of which are concurrent.

The first goal was holding up the runway beam and doing so without the bottom flange connected to any supporting structure so the trolley could move unimpeded. Resolving forces applied to the bottom flange requires the bottom flange to be larger than the top flange for the strength to support the vertical loads, but also for the stability to resist the transverse loads; a load path to transmit Cs from the bottom flange of the runway beam to the building structure was conceived using stiffener plates and outriggers tied back to the building columns.

The first goal was holding up the runway beam and doing so without the bottom flange connected to any supporting structure so the trolley could move unimpeded. Resolving forces applied to the bottom flange requires the bottom flange to be larger than the top flange for the strength to support the vertical loads, but also for the stability to resist the transverse loads; a load path to transmit Cs from the bottom flange of the runway beam to the building structure was conceived using stiffener plates and outriggers tied back to the building columns.

With the load path making its way back to the primary structure, the building columns had to be designed to accommodate not only the regular vertical downward gravity loads generating axial compression but also the remaining five degrees of freedom: torsion, strong- and weak-axis bending and shear in both horizontal planes.

Employing the building columns on grids that were coordinated for programming at various stories elsewhere in EXP essentially to eliminate the unnecessary redundancy of dedicated crane columns and also to keep the robotics lab as open as possible – the wide-flange column shapes were plated between flanges to form a box shape column most efficient for resisting so many concurrent loads, and also for minimizing deformations under the static and dynamic loads from the crane.

Putting all of the components together brings EXP to life and showcases the work happening at Northeastern. EXP is much more than a building; it allows visitors and users to witness the thrilling intersection of technology and design while beckoning individuals to peer into the world of possibilities. If there ever was doubt about EXP earning its title as the “Exciting Place,” the combination of glass transparency, robot innovation, crane choreography, and research visibility unequivocally solidifies its claim. EXP stands not just as a structure but as a testament to the relentless pursuit of excitement in the realm of scientific discovery at Northeastern.