Close

The design of tall buildings is integral to LeMessurier. From Citicorp to the Dallas Main Center, the Beijing Yintai, and the Hub on Causeway, towers designed by LeMessurier can be found across the country and all over the world. Our designs have transformed some of the most challenging sites into tall buildings that enhance the built environment and offer extraordinary value to our clients. Our team, the next generation of innovators and high-rise experts, brings the technical expertise, experience, and partnerships necessary for the success of any tall building project.

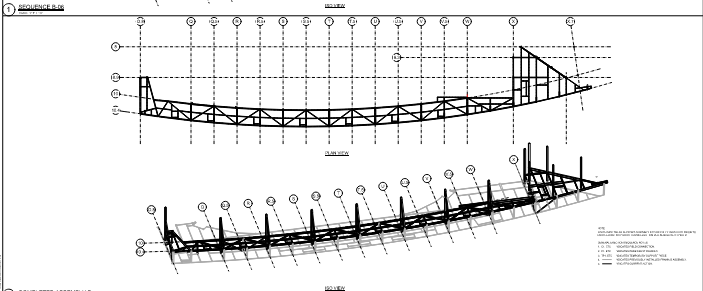

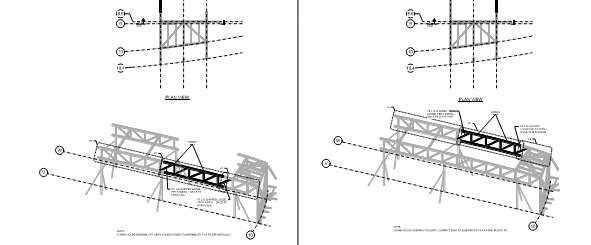

Long-span structures are among the most dramatic expressions of structural engineering. Sports arenas, stadiums, field houses, theaters, and convention centers all offer wide, unobstructed spaces that require long-span structural solutions. More than just carrying load over an open space, the structural performance and movements of long-span structures are carefully considered and incorporated into the overall design. From construction sequencing to coordinating systems for acoustics, lighting, environmental conditions, and maintenance, LeMessurier delivers projects that perform at opening and for years into the future.

Designing and delivering projects around transit systems is an art that requires the full commitment and expertise of each member of a multi-disciplinary project team. Each element of the project must not only work within the building itself, but it must serve an adjacent, existing, highly specialized, and highly regulated transit infrastructure. Such projects can require multi-agency review and coordination far beyond typical requirements of the building code. This dedicated and varied attention from multiple project stakeholders highlights the importance of the completeness, accuracy, and reliability of the structural design and project documentation.

By extending the built environment into the space above underdeveloped sites or transit thoroughfares, Air Rights projects stitch back together the often-bisected urban fabric of neighborhoods, communities, and cities. Restrictive site conditions, prescriptive regulatory requirements, and oversight by multiple stakeholders are common obstacles, but LeMessurier has the experience and unique skill sets required to deliver these truly transformational projects successfully. Our knowledge of both the transportation and building codes, as well as our ability to think outside the box, makes us ideal partners to help in overcoming the technical demands of Air Rights projects.

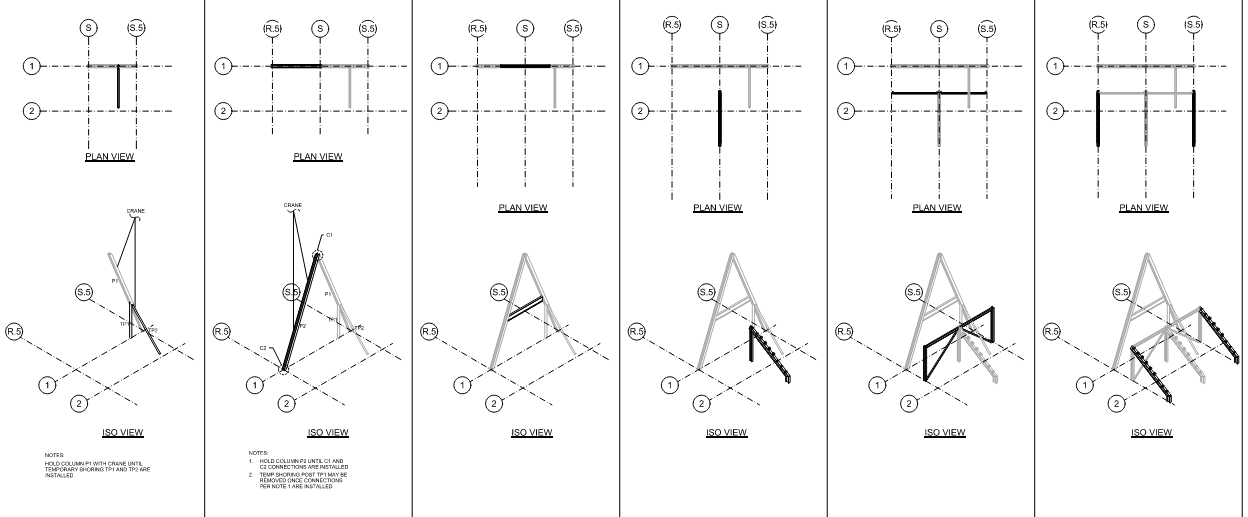

At LeMessurier, we pride ourselves on being a reliable project partner who will work with the construction team to support the logistics required to make a project a reality. Whether it be through our role as structural engineer of record for a project, our intimate knowledge of a specific type of construction technique, or even our willingness to be on-site to solve an unanticipated challenge, LeMessurier is poised to engage with existing or temporary conditions in any manner that keeps the project moving.

Improving and renewing an existing building presents distinctly different technical challenges from new building design. Preferred methods of repair, restoration, or the augmentation of existing materials change as the state-of-the-art evolves. We focus on engaging with professional designers, contractors, and material producers to keep current and add to our expertise. When a unique condition arises, we assess and propose various options and strategies for intervention that are sensitive to the cost, schedule, effectiveness, and durability of a renovation or restoration project. LeMessurier leverages our experience in historical building materials and techniques to accomplish renovations that inherently help to minimize embodied carbon impacts and honor the existing buildings within our communities.

As the only structural material with the ability to sequester more carbon than is required to produce it, timber has an essential role to play in the design and construction of our built environment.

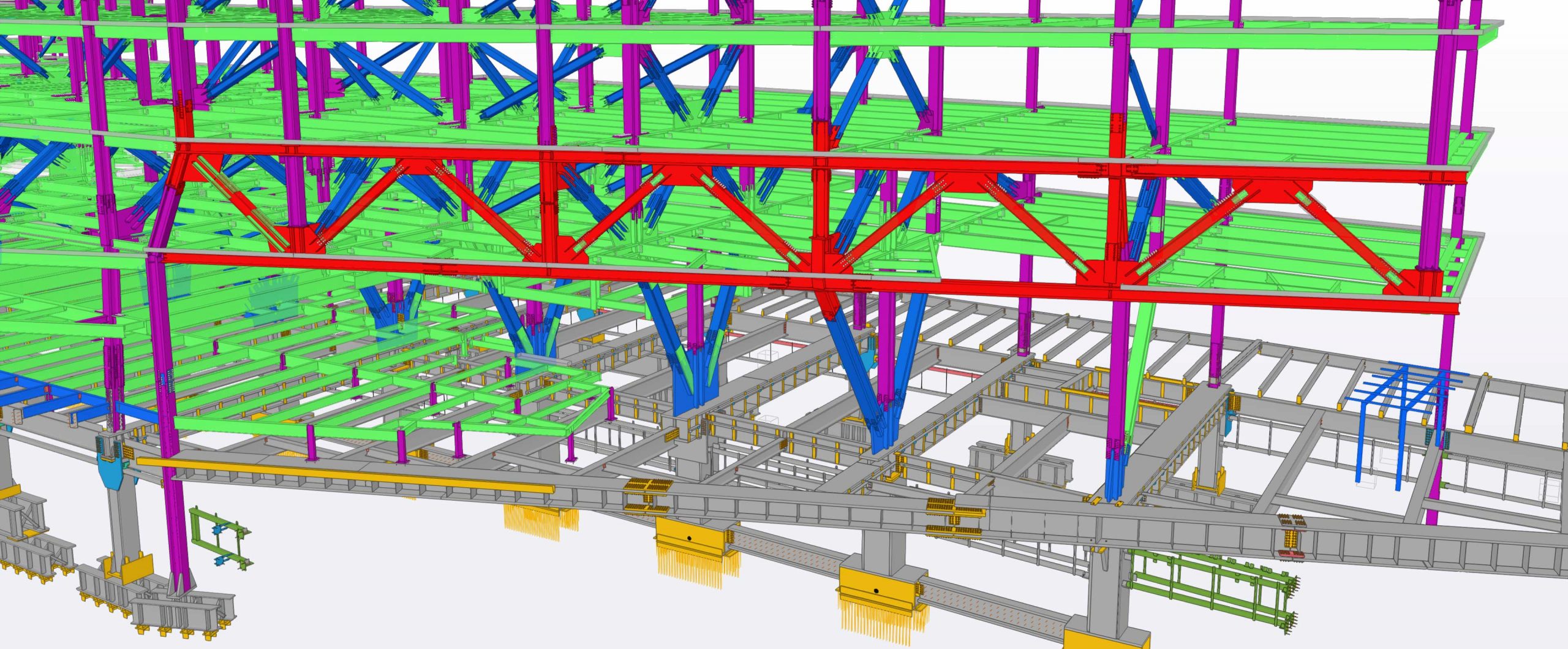

Developing a fully Connected Model through Integrated Steel Delivery is just one innovation that LeMessurier has led to reduce project overhead and minimize administrative hurdles, all in service of finding smoother and faster ways to achieve the same great product.

We are also at the leading edge of the industry working within various forms of project teams such as Integrated Project Delivery, Integrative Design Process, Owner-Controlled Team Project Delivery, and Design Build – all of which augment and offer alternatives to the traditional design-team arrangement.

Keeping an open mind, being always on the lookout for ways to improve ourselves and our engineering and project delivery is in our DNA as a firm. We continually improve the process and experience for all of the team members that our work influences.

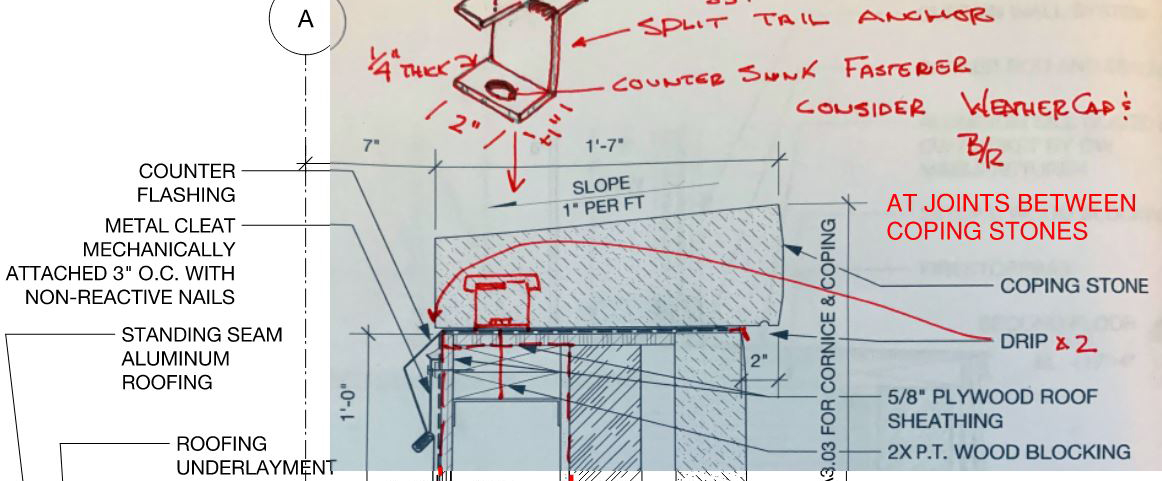

Conditions assessments are critical to understanding a building enclosure’s performance. Our team investigates and documents the current condition of critical building assemblies and materials, necessary for accurately diagnosing building performance issues and predicting potential future weaknesses. We evaluate vital building materials, assemblies, and systems from the micro to the macro scale, ensuring that we have a cohesive picture of any failures and their affiliated design remedies for our clients. Beyond pointing out problems and potential solutions, we are sensitive to our client’s competing capital priorities, and we make recommendations for repairs, mitigation, and risk management accordingly.

Forensic investigations help our experts better understand existing assemblies with observational information on how the building is constructed and functions. When as-built conditions do not exactly match as-built documentation, selective forensic investigations help fill the gaps. Additionally, these investigations often expose damage caused by underperforming enclosures and are used to define a more accurate project scope for a repair or restoration project. Beyond the transactional work for our clients, we see each investigation as an opportunity to improve our knowledge base, our team’s capabilities, our practice, and the current state-of-the-art in building science. As active members of several industry organizations, we take the obligation to share our expertise seriously.

Architects and designers often require or desire a review of critical enclosure details during design, and LeMessurier offers varying levels of peer review services during this process. Whether it is incremental design and review charrettes prior to key deliverable dates, review of enclosure-related submittals and RFIs, or participating in a punch list site meeting, we provide expert peer review services to prevent, mitigate, or remedy issues, improving constructability and performance.

Feasibility studies provide an opportunity to help our clients understand their options. Many enclosure projects begin with an array of options and concepts, often ranging from repairs to restoration to assembly replacement. By taking the time to study each of these options, we can understand their impacts on cost, energy performance, historic preservation, code implications, and long-term performance, amongst others. This provides our clients with the crucial information they need to make decisions about their buildings going forward.

Having licensed architects and engineers in-house enables our team to provide full enclosure design services. Whether it is following up on the design recommendations from one of our Findings Reports, re-cladding an existing building with a new assembly system, or providing window and roof replacements, we provide design services from programming through construction administration.

Constructing a successful enclosure design, whether a high-performance system, a recladding, addition, or repair, requires expert construction and installation. Our team is adept at Construction Administration or assistance with bid services, RFI review, submittal review, site observation, and mockup coordination. Building enclosure design is only as good as execution. The vast majority of failing wall and roofing systems result from construction errors or missed details. Special care around the building assemblies and critical details for the enclosure’s performance, insuring those items are installed correctly in the field is our top priority.

Building performance testing for new construction ensures that systems are acting as designed and saves time, aggravation, and money identifying weaknesses before occupancy. We can test new construction and assembly mockups. In existing, underperforming, or troubled construction, testing generates critical information to identify the causes and potential solutions for enclosure failures. From water infiltration testing for roof, window, and wall assemblies using AAMA / ASTM guidelines, to monitoring building or seismic movements before, during, or after construction, our team has the equipment and expertise for efficient and accurate building performance testing.

Through a culture of collaboration and a legacy of innovation, our approach is to explore – early in design – opportunities to reduce embodied carbon.

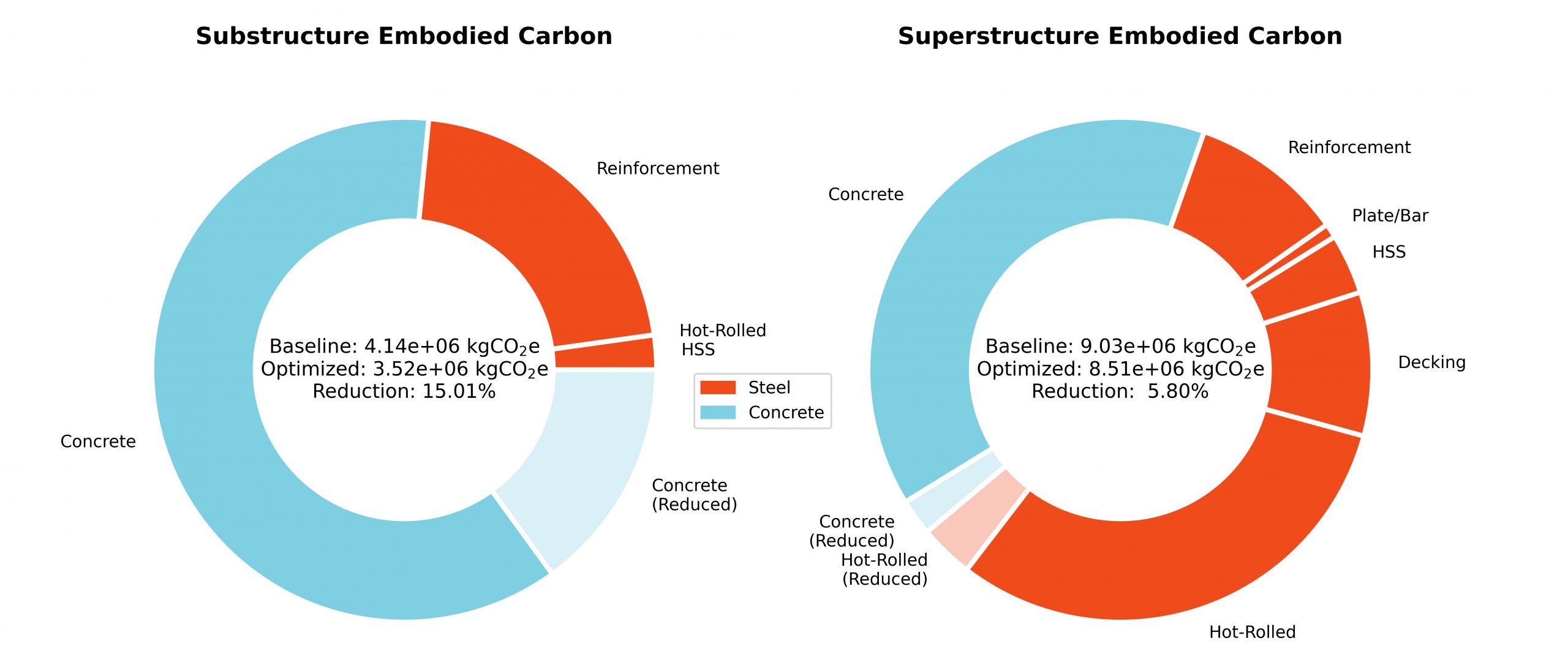

Embodied carbon in the built environment is generated in raw material extraction, in the manufacturing and transportation of building materials, in the construction, maintenance, and demolition of a building, and finally, in the disposition of its materials at the end of life. Structural systems can constitute up to 50% of a building’s total embodied carbon. Early in our projects, we explore options for structural design, material alternatives, and how to optimize materials in construction. We also explore the source of the materials on a project, the use of salvaged structural steel, and the durability and deconstruct ability of our designs.

LeMessurier incorporates education, advocacy, and the reduction of embodied carbon into our practice. We have committed to complete structural life cycle carbon assessments for all our projects.

As a co-founder, chair, and signatory of the SE 2050 program, LeMessurier works with both key industry professionals and our clients to explore and execute solutions leading to reduced embodied carbon in the built environment. We collect embodied carbon data from our projects and our vendors to both gauge our performance and to expand the knowledge base for the AEC community, sharing our goal: to achieve net zero embodied carbon structures by 2050.

LeMessurier Embodied Carbon Action Plan

www.se2050.org

Learn about the SE 2050 Challenge

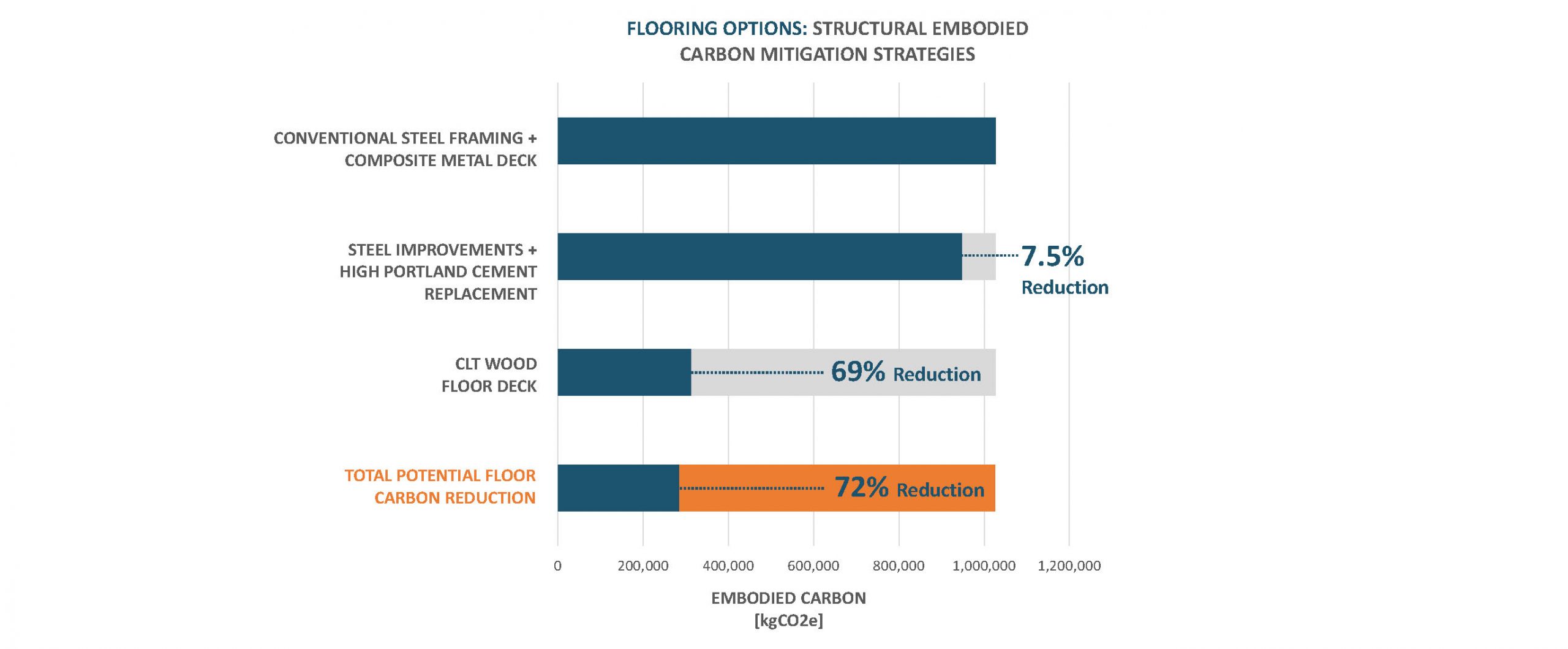

The material with the largest potential to reduce embodied carbon in the built environment is Mass Timber.

We work with project design teams to explore mass timber options, which include everything from sustainably sourced full mass timber structures to steel-timber hybrids or structural timber components such as Cross Laminated Timber (CLT) floors or CLT shear walls.

Beyond the embodied carbon benefits, mass timber allows buildings to be constructed faster, with lower labor costs and less waste. As its use increases, we are working to provide data and analysis to inform appropriate revisions and additions to the building code for structural code and fire rating agencies.

LeMessurier’s experience with mass timber allows specific clients of ours to re-imagine what is possible in a life sciences laboratory environment. To support vibration-sensitive, high-performance lab buildings, we completed comparative studies of mass timber systems with conventional steel and concrete systems, demonstrating mass timber’s effectiveness for this specialized building type.

We are currently participating in a 2022 Wood Innovation Grant from the U.S. Forest Service to demonstrate mass timber as a climate solution in three U.S. cities with the goal of scaling up its use and encouraging investment in U.S. manufacturing.

Early-stage analysis explores the design and material options resulting in informed design decisions and optimized embodied carbon reductions.

A Life Cycle Assessment (LCA) in construction evaluates the environmental impacts throughout the entire life cycle of the building, including upstream and downstream processes associated with the production and disposal of construction and finish materials. Our team provides an LCA at each design phase and offers suggestions for reducing embodied carbon while meeting the design intent.

Every project needs a sustainability champion. At LeMessurier, we believe every team member should be that sustainability champion.

We go beyond analysis and developing designs with low embodied carbon; we find solutions. We work with the project design and construction teams, local material suppliers, and manufacturers to remove barriers and push the boundaries of what is considered “business as usual” without sacrificing the budget or life safety.

Our advocacy has resulted in industry breakthroughs such as a record-setting ratio of portland cement replacement for the Boston and northeast regions and bringing ground glass pozzolans to the local market despite an assumed price obstacle. This collaborative approach allows us to push the boundaries of what owners, designers, and construction teams think is possible.

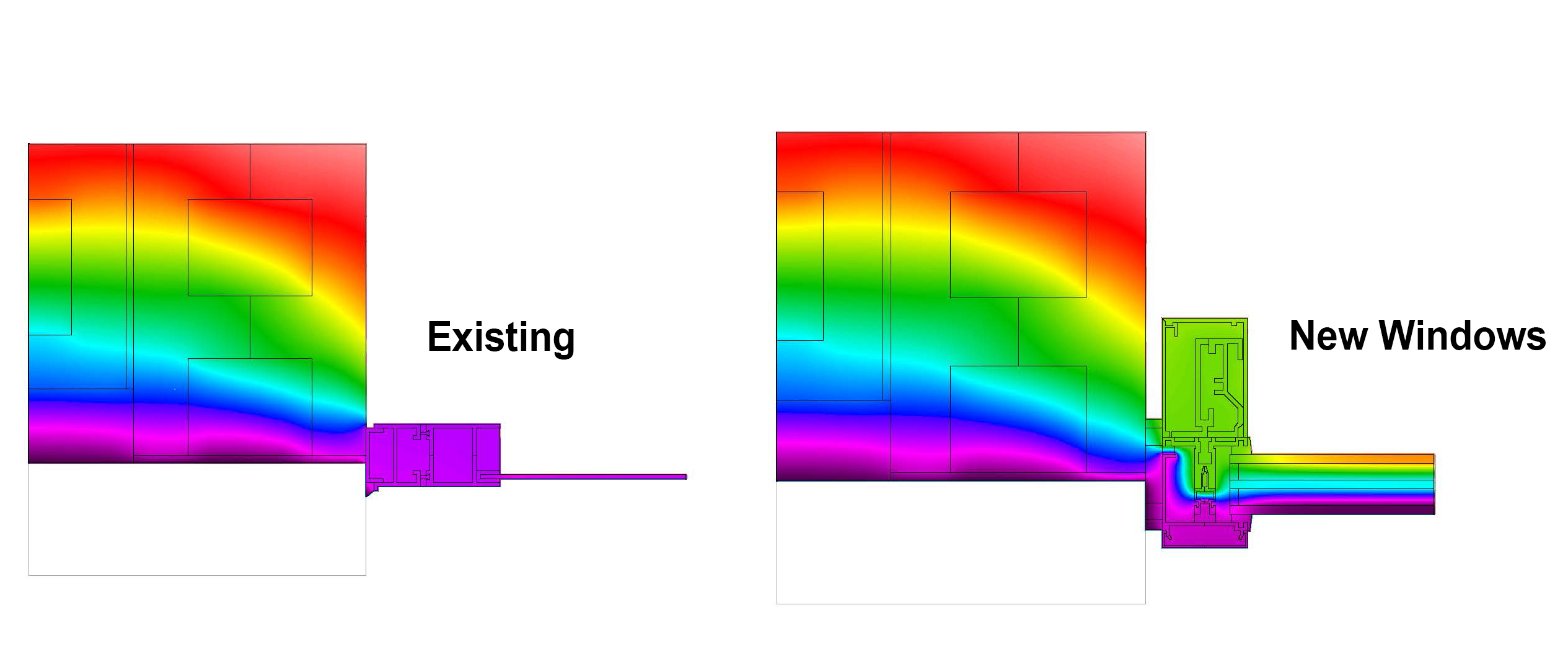

Reductions to embodied and operational carbon come together in high-performance enclosure systems.

Proper design and execution of enclosure systems can optimize many sustainable performance factors, including thermal, visual, acoustic, and air quality. A holistic approach to whole-building, resilient design will account for these factors and leave options for future flexibility.

When studying the carbon impact of different components, we look at both the embodied carbon of the material and the operational carbon saved together in the form of a “carbon buyback period,” that quantifies how many years of operational carbon savings are needed to compensate for the material’s embodied carbon.

The single most impactful strategy for reducing embodied carbon in the built environment is to renovate and extend the life of existing structures through adaptive reuse.

As structural engineers and building scientists, we enjoy the challenge of bringing new life to existing buildings through adaptive reuse. Throughout our history, our structural and enclosure group has worked on renovating, refurbishing, and re-skinning some of the most exciting and inspiring buildings. In several cases, we have been able to revisit our own original projects and reposition them for a new century.